Case

Centrifugal Spinning machine for Prestressed concrete pile production machine

Product Category

Key word

Centrifugal Spinning machine

concrete pole centrifugal spinning machine

concrete pole centrifugal spinning machine

Email:

Phone/WeChat:

Details

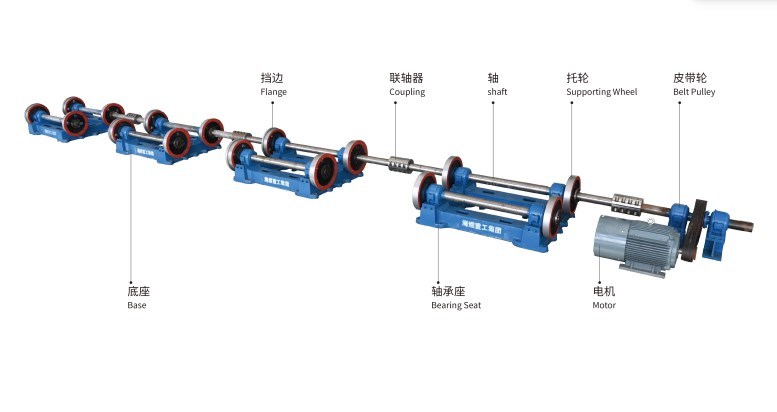

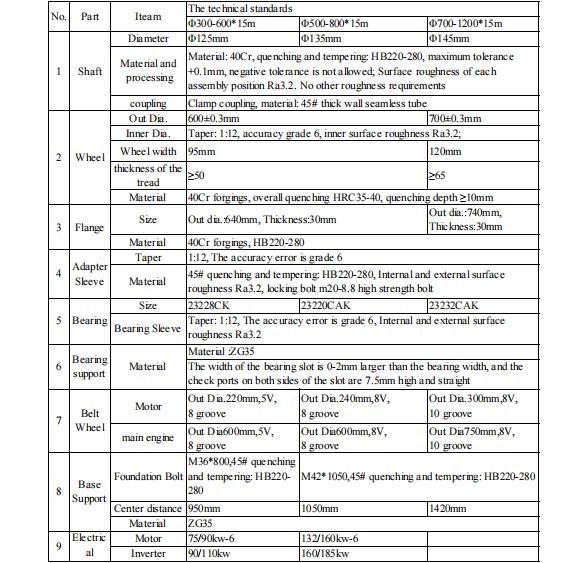

The principle of the concrete pole Centrifugal Spinning machine is to transmit the power of the motor to the driving wheel through belt drive and use the friction between the driving wheel and the steel mold running wheel to drive the prestressed concrete pile steel mold to rotate, so as to achieve the purpose of concrete centrifugal forming. Now the Centrifugal Spinning machine generally adopts frequency conversion technology, and energy consumption is greatly reduced.

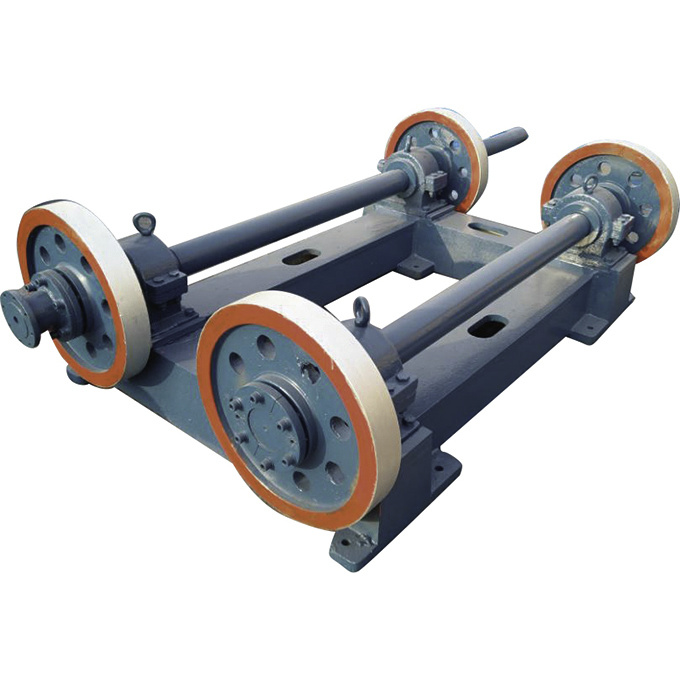

Centrifugal Spinning machine is mainly composed of driving wheel train and driven wheel train. Each pair of driving wheel is connected into a whole by a coupling, and the driven wheel pair is disconnected. See the product diagram for details. When the pipe pile centrifuge is working, the power source is provided by the motor. The motor transmits the power to the driving wheel system through the belt wheel. The driving wheel system drives the steel mold to rotate by the friction force, and finally the steel mold drives the driven wheel system to rotate. The steel mold is equipped with concrete cloth, which is centrifugal formed in this process. Friction and collision occur between the pipe pile mold and the supporting wheel of the centrifuge during high-speed centrifugal operation, and friction occurs between the supporting wheel and the pipe pile mold and the air during high-speed rotation, which can produce great noise. After testing, the highest noise can even reach 110dB(A).

As a large energy consumption equipment, how to save energy and reduce emissions has naturally become the focus of the design of Centrifugal Spinning machine. The use of frequency control technology, to achieve full automatic operation, the reliability and stability of centrifuge has been greatly improved, the centrifugal process has been better implementation, the quality of pipe pile has been better improved. Centrifugal technology is an indispensable means for concrete pipe pile compaction forming. The centrifugal technology directly affects the concrete strength of pipe pile. According to the requirements of centrifugal process, the frequency conversion speed regulating technology can be set into different running speeds and running times for different specifications of pipe piles in the process of slow stirring - medium speed compaction - high speed forming, to achieve automatic digital control. At the same time, because the acceleration time of different centrifugal stages can be set arbitrarily, it can effectively prevent the uneven wall thickness and caking phenomenon caused by too fast acceleration, and prevent the current impact caused by too fast acceleration.

Our Centrifugal Spinning machine adopting frequency control technology, the centrifugal speed is stable and the precision is high. The core parts of frequency conversion speed control by high-performance microprocessor digital control, can effectively ensure that the speed is not affected by changes in environmental temperature, speed change rate within 0.5%, automatic operation, the speed rises smoothly, will not appear up and down phenomenon. The impact on the centrifuge itself is small, for steel mold and centrifuge have a protective effect, plays a key role in the stability of product quality.

Recommended Products

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

The products involve pipe pile centrifuge, pipe pile steel mold, square pile steel mold, electric pole steel mold, seam welder, automatic cutting head equipment, chain machine, steel mold automatic fixture...