Case

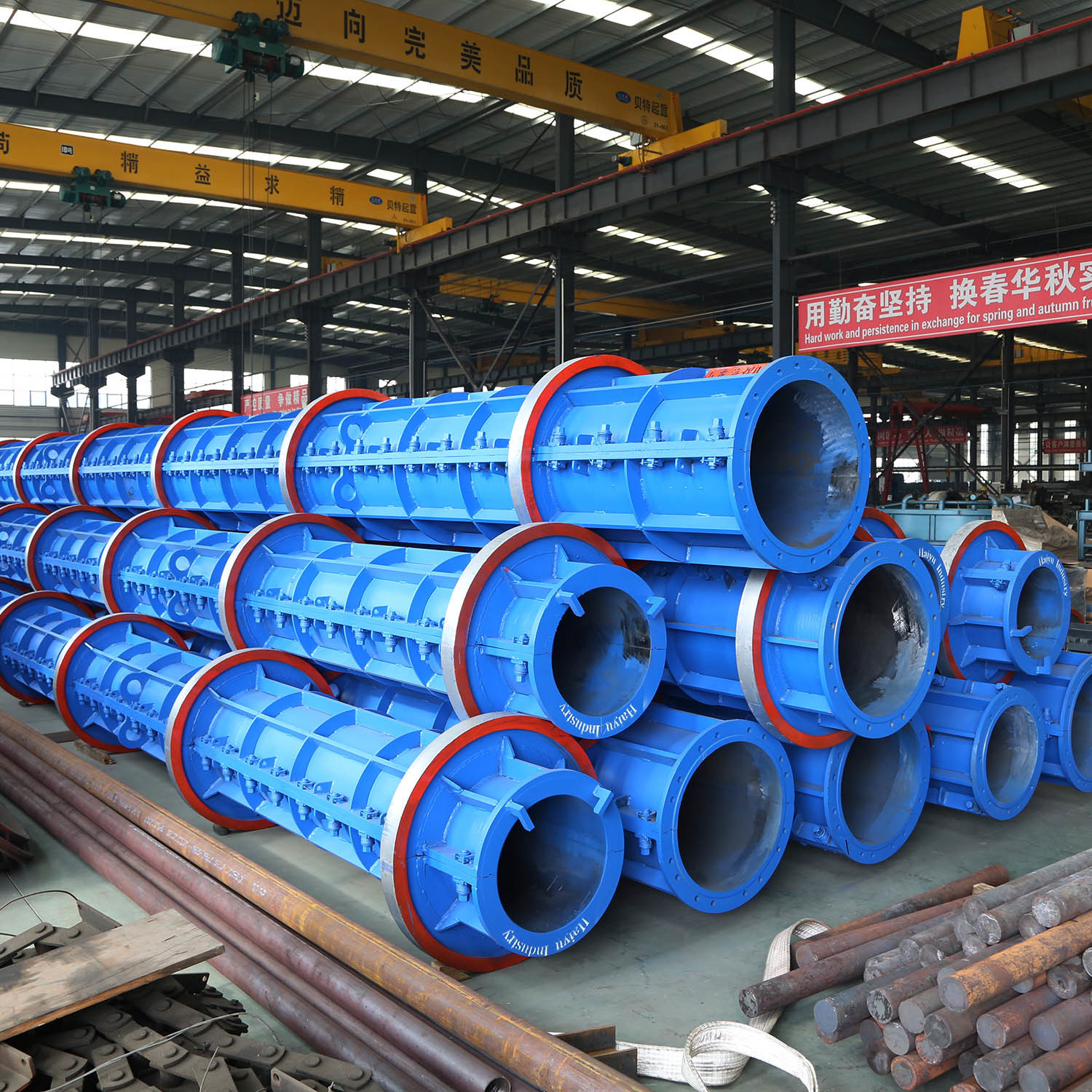

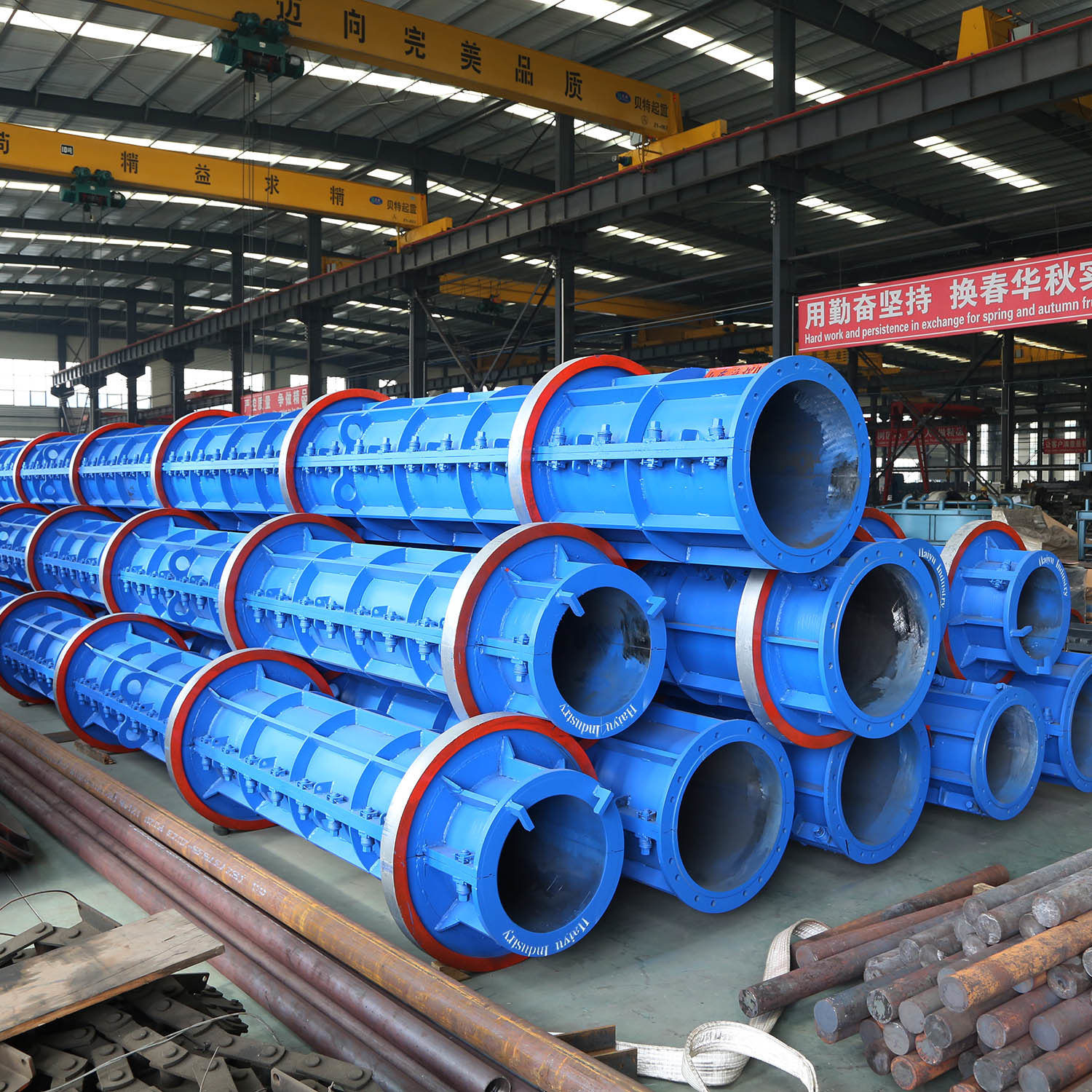

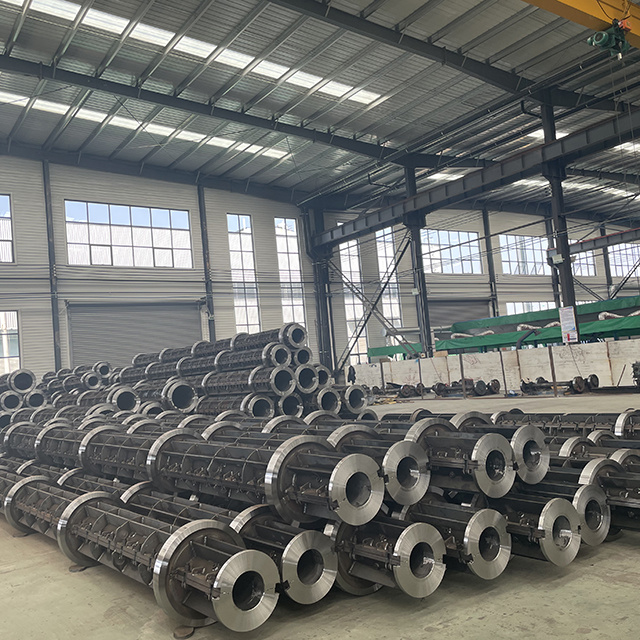

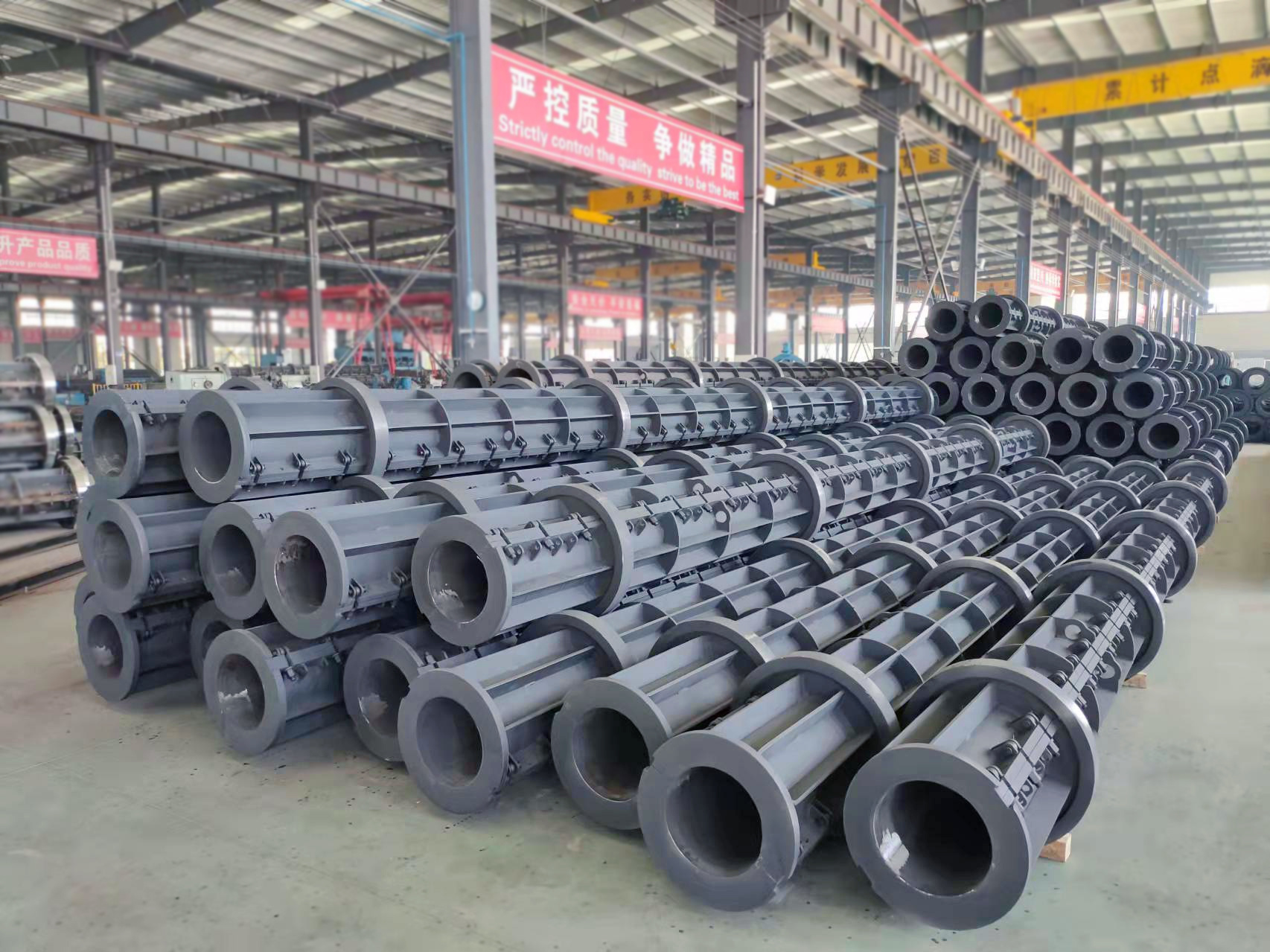

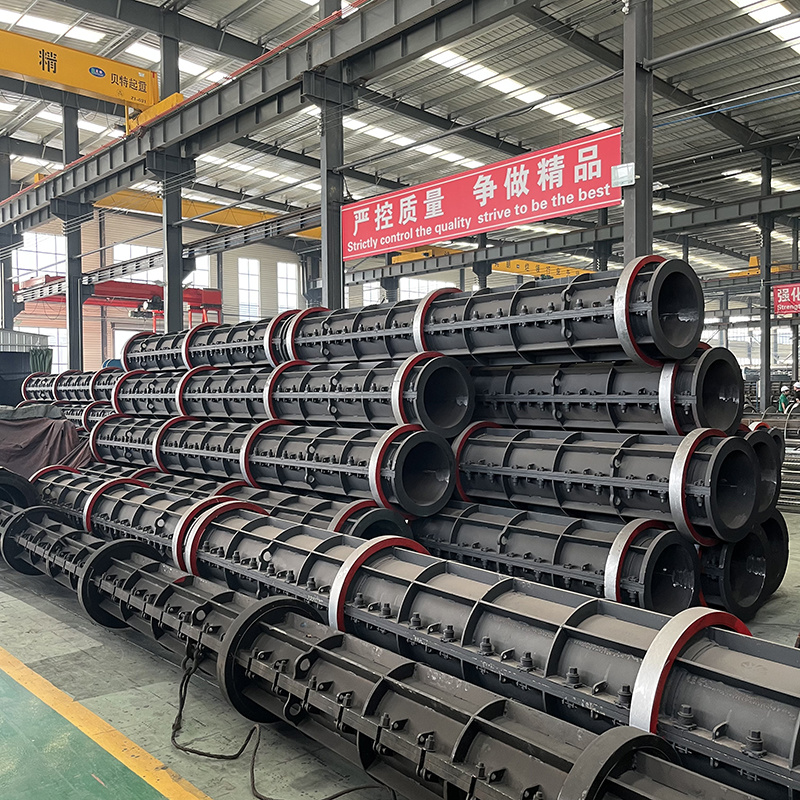

Spun concrete pole mold

Product Category

Key word

Concrete pole mould

concrete pole mold

Prestressed concrete pole mold

concrete pole steel mold

Email:

Phone/WeChat:

Details

Concrete pole mould is used to shape the concrete pole , there are two kinds of concrete pole usually , Prestressed concrete pole and reinforced concrete pole . The mold shape determine the pole shape , the cross-section of concrete pole is square, octagonal, I-shaped, circular or other special-shaped . To produce different cross-section , with ddifferent shape concrete pole mould.

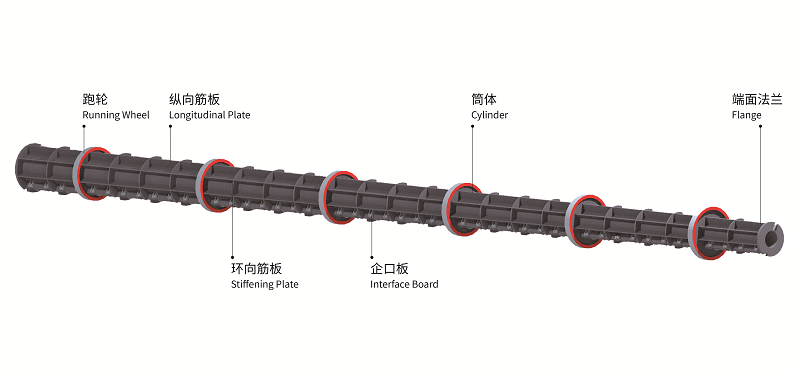

Here is mainly introduce Spun concrete pole , the spun concrete pole is with two kinds , tapered concrete pole and equal-diameter concrete pole , The tip diameter of the tapered pole is generally 100-230 mm, and the taper is 1:75; the diameter of the equal-diameter pole is 300-550 mm; the wall thickness of both is 30-60 mm

Herer introduction is the tapered concrete pole Mould .

Concrete pole mold is compsed of upper mold , Down mold , barrial , spiral plate , longitudinal plate , running wheel .

The concrete pole steel mold is working with centrifugal spinning machine ,the mould rotates in in the force of centrifugal , After 10-15 minutes of rotation at different speeds,Moisture flung out of concrete,and Concrete is dense and evenly distributed on the inside of the mold, then during 4 hous steam curing , the concrete pole is produced.

Its manufacturing process is mainly to stretch the steel wire skeleton longitudinally in the steel mold, and then make the concrete squeeze out excess water under the action of centrifugal force, thereby greatly improving the compactness and strength of the concrete.

Recommended Products

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

The products involve pipe pile centrifuge, pipe pile steel mold, square pile steel mold, electric pole steel mold, seam welder, automatic cutting head equipment, chain machine, steel mold automatic fixture...