Case

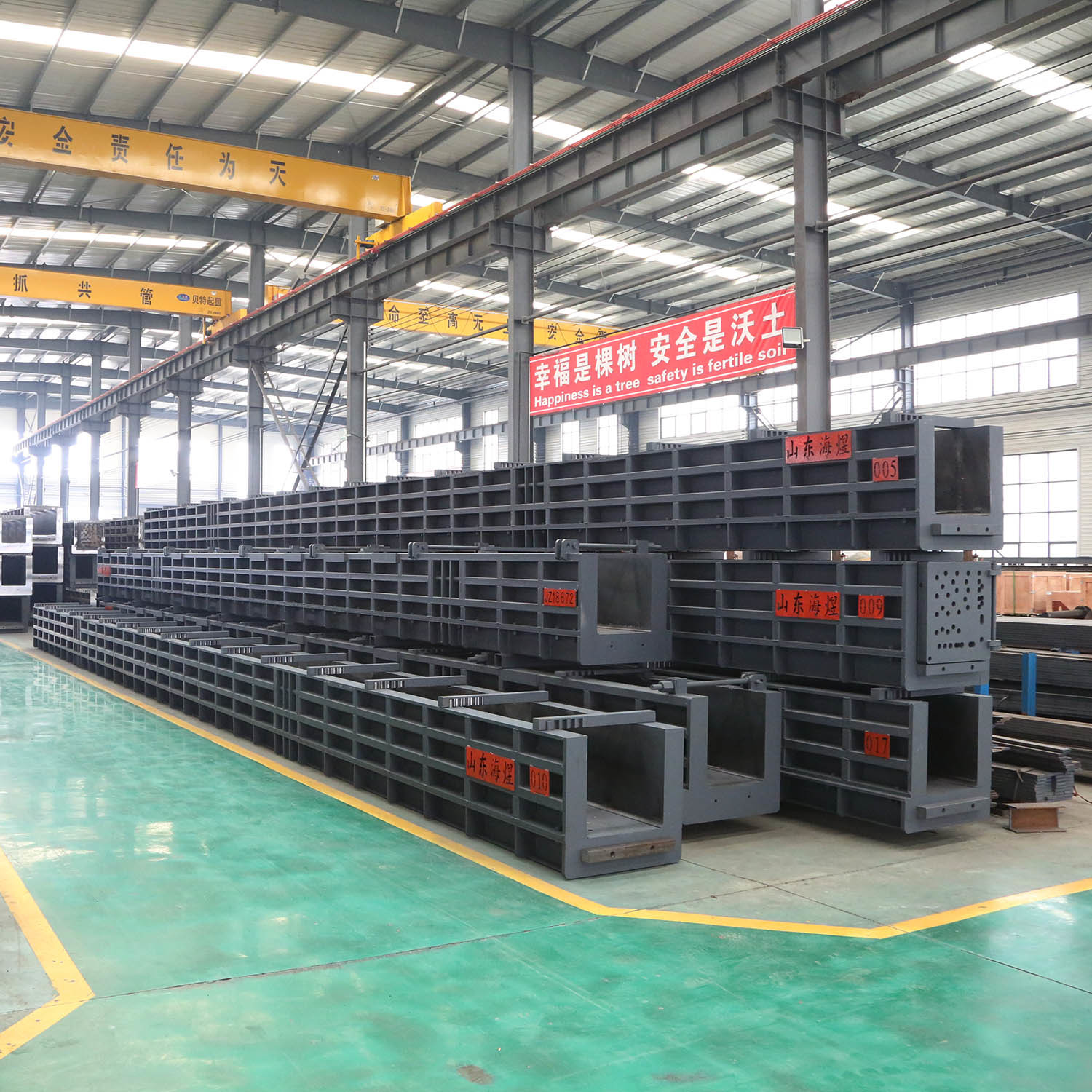

Solid Square concrete pile mold

Product Category

Key word

Email:

Phone/WeChat:

Details

Solid Square concrete pile mold adopts assembled structure, which has high rigidity and is not easy to deformation, so as to ensure the appearance size of prefabricated solid square pile. The design of the side die with a half I-shape cross section and the setting of the reinforcement plate between the upper flange and the lower flange all increase the section moment of inertia of the square open groove, improve the mold stiffness and improve the deformation resistance. In addition, the setting of the tie rod at the upper part of the square open groove ensures the appearance size of the prefabricated solid square concrete pile.

First,The solid square concrete pile mold has the advantages of simple and reasonable structure, large stiffness, easy deformation, long service life and so on. Through Angle steel, channel steel, rectangular pipe, connecting plate and setting reinforcement plate on the side plate of the mould, rectangular pipe under the bottom plate of the mould and fin plate on the rectangular pipe, this whole set of structural design greatly improves the rigidity of the mould and the bending ability is significantly improved. The appearance size of pile body is effectively guaranteed.

Second,The adjusting screw is set equidistant on the upper edge of the side plate of the solid square concrete pile mold. The adjusting screw can avoid strengthening the lateral force of the mold, so that the side mold will not tilt outward under the pressure of concrete and the pile cannot meet the strength requirements, which can effectively improve the work efficiency and reduce the production consumption.

Third,the internal size of the square opening slot is convenient to adjust, and a set of mold can produce a variety of specifications of prefabricated solid square piles. Usually prefabricated solid square pile cross-section size has a variety of specifications, the length according to the engineering needs design, from several meters to tens of meters. By adjusting the assembly position of the side formwork on the bottom plate, a set of mold can produce concrete square piles of various specifications, which reduces the specifications of the mold and improves the utilization rate of the mold. Moreover, the reduction of mold specifications is also conducive to the management of molds, such as stacking and maintenance.

Recommended Products

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

The products involve pipe pile centrifuge, pipe pile steel mold, square pile steel mold, electric pole steel mold, seam welder, automatic cutting head equipment, chain machine, steel mold automatic fixture...