Case

Concrete pipe steel cage welding machine

Product Category

Key word

Concrete pipe welding machine

cage welding machine

Email:

Phone/WeChat:

Details

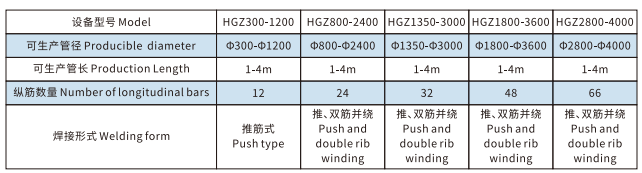

Drain pipe welding machine replaces manual processing and simplifies the complex and difficult-to-manual processing process. In the production of steel cages, on the basis of manual assistance, the main reinforcement feeding, stirrup straightening and winding, stirrup and main reinforcement welding and other processes are automatically completed. The advanced automatic production equipment greatly improves the processing efficiency and product quality, and the older products have optimized multiple important structures, making them more reasonable and greatly reducing the cost, and the equipment is more competitive in the market.

Widely used in the construction of high-speed rail, high-speed and other projects. The steel cage machined by the steel cage winding machine has high precision and small error. The error of two adjacent reinforcement windings is within 3mm. Using a meter ruler to directly pull the length of 3 meters, the total error Within 2CM, it is basically a product inspected by the project department

Due to the use of numerically controlled mechanized operations, the drainpipe roll welding machine has uniform spacing between the main ribs and winding ribs, and the diameter of the steel cage is consistent. The product quality fully meets the specification requirements.

Recommended Products

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

The products involve pipe pile centrifuge, pipe pile steel mold, square pile steel mold, electric pole steel mold, seam welder, automatic cutting head equipment, chain machine, steel mold automatic fixture...