Case

Concrete pole spinning machine

Product Category

Key word

concrete pole centrifugal spinning machine

customized concrete pole spinning machine

Email:

Phone/WeChat:

Details

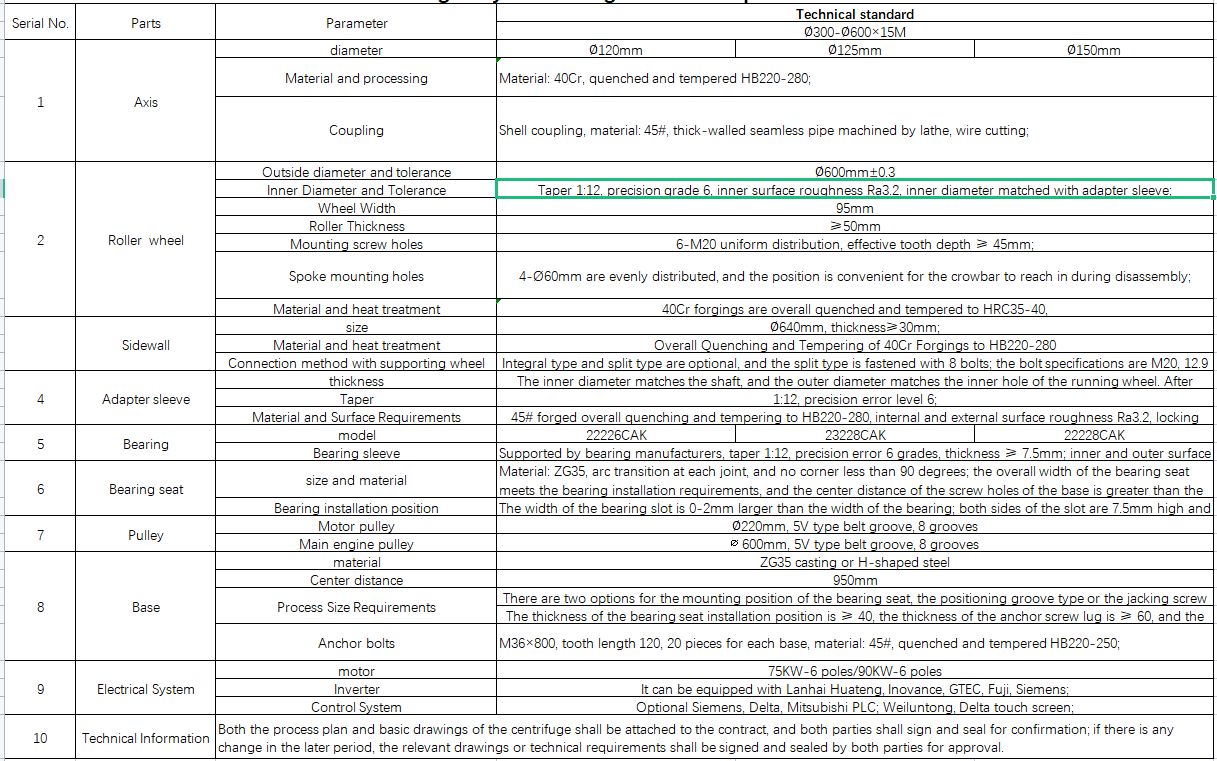

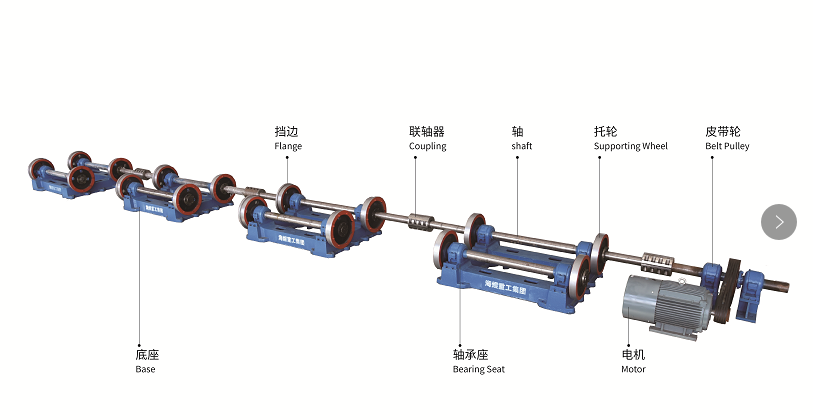

The concrete pole centrifugal spinning machine Rotates the driving shafts through the motor, which rotates the driving wheel, The driving wheel drives the mold to rotate through the friction generated with the mold, during the rotation of the mold, the concrete is evenly distributed along the inner wall of mold under the action of centrifugal force, It is compacted under continuous centrifugal action, and the concrete/steel bars are effectively combined to form a preliminary concrete ground pole through centrifugal molding at low speed/medium-low speed/medium speed/medium-high speed/high speed and other stages.

The spinning machine is forming pre-tensioned prestressed concrete piles, electric poles, photovoltaic piles and hollow square piles.

1.It is Composed of pulley, motor and control part, the operating speed generally has five stages, low speed, medium-low speed, medium speed, medium-high speed and high speed. Through these five stages of speed, the excess water and air in the concrete in the mold will be discharged to form. PHC pipe piles, electric poles or square piles. The main advantages of the centrifuge produced by our company are as follows: 1. Shaft: the material is 40Cr, quenched and tempered to HB220-280, with high yield strength, and it is not easy to cause quality accidents such as broken shaft.

2. Supporting roller: The material is 40Cr forging, and the overall quenching and tempering is HRC35-40. It has strong impact resistance and good wear resistance. Users can choose integral ribs and live ribs.

3. Adapter sleeve: The material is 45# forging, quenched and tempered to HB220-280, and the yield strength is ≥355MPa.

4. Bearings: High-quality bearings from Wafangdian Bearing Co., Ltd. are selected. The comprehensive economic and technical indicators rank first in the domestic bearing industry and twelfth in the world.

5. Bearing seat: the material is ZG35; 6. Base: the material is ZG35 or H steel (Q235B), the user can choose the traditional ZG35 casting base and the H steel integral base.

6. Electrical system: Due to the deformation of individual pipe pile molds or irregular mold clamping, mold jumping and flying molds will occur during high-speed centrifugation, which is a major hidden danger in production safety.

Recommended Products

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

The products involve pipe pile centrifuge, pipe pile steel mold, square pile steel mold, electric pole steel mold, seam welder, automatic cutting head equipment, chain machine, steel mold automatic fixture...