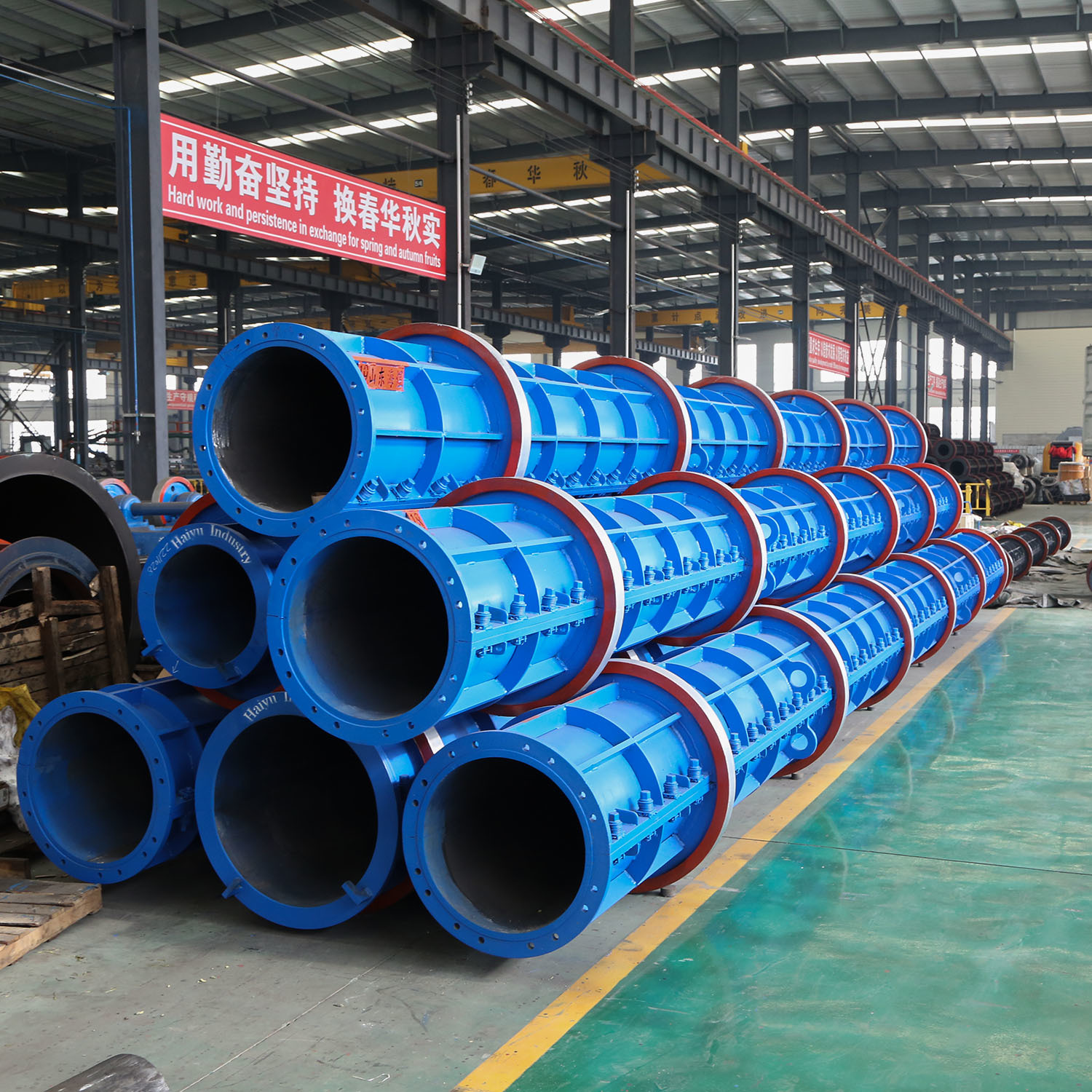

Case

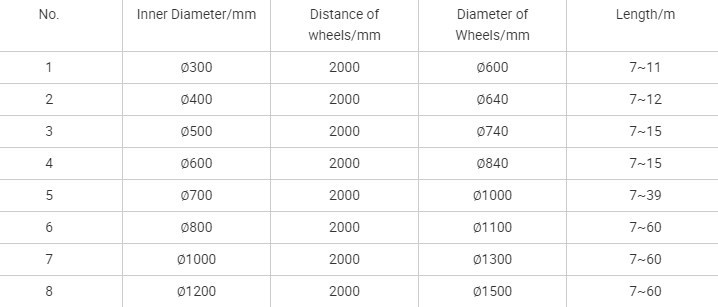

D300~1200MM prestressed concrete pile steel mold

Product Category

Key word

prestressed concrete pile steel mold

concrete pile steel mold

concrete pile mold

Email:

Phone/WeChat:

Details

Working Principle

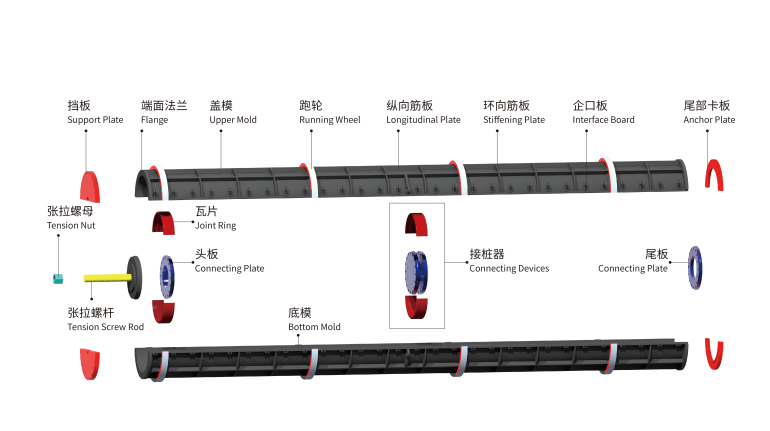

Working PrinciplePrestressed concrete pile steel mold is one of the important equipment in pile production. It is not only the mold of modeling, but also the equipment of prestressing. Due to the effects of centrifugal force, vibration force, thermal stress and fatigue stress in the production process, it is easy to produce deformation and even failure. Therefore, in the design, in addition to meet the requirements of the size to be accurate, simple structure, disassembly to be convenient, but also must have enough strength and stiffness.

First. The Prestressed concrete pile steel mold cylinder is cut according to the size ordered by customers. The maximum length of the cylinder is 6m, and the welding seam of the cylinder is less, which reduces the influence of welding deformation and the error of manual docking; The material can be Q235B or Q345B.

Second, The Prestressed concrete pile steel mold running wheel is made of forging material or cast steel material, and the running wheel welding is made of automatic Panasonic robot, with high welding strength and low stress.

Third, The Prestressed concrete pile steel mold adopts the welding process, the welding process is carbon dioxide welding, the gas is mixed, the welding machine adopts the panasonic welding machine, the welding spot is beautiful, no welding slag.

Fourth, the introduction of 18m ultra-long lathe, under 12m steel die integral lathe processing, improve the concentricity of the steel die.

Five, can be configured according to customer requirements of the reinforcement plate and flange size, optional 12×63mm or 20×63mm size.

Six, the steel die interface plate from the previous longplaner processing technology to milling machine processing technology, improve the production efficiency and quality stability.

Recommended Products

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

The products involve pipe pile centrifuge, pipe pile steel mold, square pile steel mold, electric pole steel mold, seam welder, automatic cutting head equipment, chain machine, steel mold automatic fixture...